5 Considerations for Choosing an Asphalt Sealcoat

Adding an asphalt sealcoat to your pavement preservation plan will help prolong the life of your asphalt. With dozens of sealcoat products out there, choosing the right sealer for your parking lot or driveway can be difficult. While weighing your options, consider the following factors:

- Appearance: How long will the sealcoat maintain its uniform black finish?

- Chemical Resistance: Will the asphalt sealcoat stand up to common vehicle fluids like gasoline and motor oil?

- Durability: Can the sealer handle heavy vehicle and snowplow traffic? Will it flake off in high traffic or sharp-turning areas of the parking lot?

- Convenience: How long can you afford to have your parking lot or driveway closed to traffic?

- Environment: Will the sealcoat have a negative environmental impact on your community?

1. Appearance: Around 70 percent of customers sealcoat their parking lots for aesthetic purposes. After all, your parking lot is often customers’ first impression of your business. With that in mind, it’s important to choose an asphalt sealcoat that maintains its uniform black finish for longer than a season or two. Many conventional parking lot sealcoats fade from black to gray in as little as six months due to poor UV resistance.

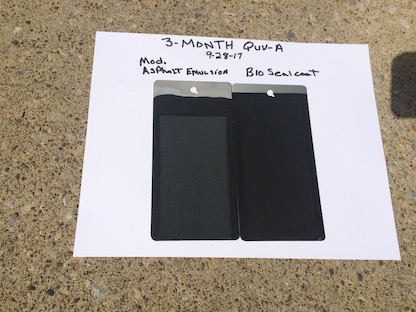

One common test method for sealcoat UV resistance is to place products in a QUV booth. The QUV booth simulates sunlight, changes in humidity, and other environmental factors a sealcoat would face in a parking lot. The picture below shows how asphalt sealcoats fared in a QUV booth after six months of testing. As you can see, not all sealcoats are created equal!

2. Chemical Resistance: Not every car parked in your lot or driveway will be in pristine condition. Vehicles visiting your lot will inevitably leak gasoline, motor oil, and other fluids onto your asphalt. Unfortunately, these fluids eat away at the binder that holds the small stones in your asphalt together because they are hydrocarbons. Prolonged exposure to oil and gasoline will leave you with loose stones, or worse, hairline cracks and potholes. Surprisingly, vehicle fluids have a similar effect on some of the most commonly used sealcoats, particularly asphalt emulsion-based products. Be sure to choose a sealcoat with excellent chemical resistance to act as a barrier between leaking vehicle fluids and your asphalt.

3. Durability: Asphalt is a flexible pavement. Its elasticity is what prevents it from becoming brittle and cracking. Unfortunately, exposure to oxygen causes asphalt to lose its elasticity. You can see this beginning to happen when asphalt starts turning gray. Sealcoating can prevent the oxidation process by acting as an oxygen barrier. To act as a barrier, the sealcoat must remain on the asphalt,thus, durability and adhesion are vital when choosing an asphalt sealcoat. If your asphalt substrate is exposed, it will begin to oxidize very quickly. Be sure to choose a sealcoat with excellent adhesion and durability to avoid hairline cracks and potholes in your parking lot.

4. Convenience: Your parking lot and driveway must be closed to traffic while your sealcoat cures. The question is, how long can you afford to keep vehicles off your pavement? Traditional coal tar and asphalt emulsion sealcoats require 2-3 days to fully cure, so crews typically spend 2-3 days at the site, closing down one section at a time to seal, cure, and restripe if necessary. Some new sealcoat products, however, cure much quicker and can allow for same day striping and traffic. The longer a product takes to cure, the more likely someone visiting your parking lot will ignore the cones and drive over the uncured sealer, leaving tire marks and ruining the uniform finish you’re looking for in a freshly sealed parking lot. And don’t forget, the extra labor and travel associated with sealcoating jobs lasting multiple days while waiting for product to cure find their way into the cost of the project! Use a sealcoat that allows for same-day traffic to minimize headaches.

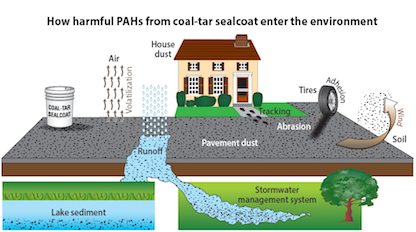

5. Environment: You’ve probably noticed the harsh odor emanating from a freshly sealed parking lot, especially one that’s been sealcoated with a coal tar-based sealer. Not surprisingly, coal tar-based sealcoats have come under regulatory fire in recent years due to their high concentration of polycyclic aromatic hydrocarbons (PAHs), a known human carcinogen. These carcinogens enter the environment through water runoff, abrasion from turning tires, and airborne volatilization while sealcoats cure.

Asphalt emulsion-based sealers contain some PAHs, but much fewer than coal tar. To minimize your sealcoat’s effect on the environment, ask your contractor or sealcoat manufacturer if their asphalt sealcoat has passed EPA 8270 testing. One low-odor product that has passed 8270 testing is BioSealcoat, a new sustainable sealcoat made from soybean oil. Your customers and your community will appreciate you applying an environmentally friendly asphalt sealcoat.