The Best Products for Sealcoating Asphalt

Your organization decided to commit to a planned preventative maintenance program for your asphalt parking lot. This entails crack filling, patching, and sealcoating your asphalt once every couple years to prevent asphalt oxidation and keep your parking lot looking new. You put the project out for bid and receive several quotes, each uses a different type of asphalt sealer. A handful call for coal tar sealers, a few plan on using asphalt emulsion-based products, and one calls for BioSealcoat®, a sustainable sealcoat made from soybean oil. Which is the best for sealcoating your asphalt?

To figure out which seal coat is best for your asphalt, it’s important to understand the benefits sealcoating asphalt is supposed to deliver:

Beautify Your Pavement

First impressions are important, and a well-maintained parking lot can set the right tone with your guests. Sealcoating asphalt helps restore your parking lot’s rich black finish. But how often will you need to reapply sealcoat to maintain a pristine finish? That often depends on the product’s UV resistance, as some sealcoats tend to chalk out and fade to gray only a few months after application.

The picture below compares BioSealcoat, an soy-based eco-friendly sealer, to a coal tar modified asphalt emulsion commonly used in the Midwest. Contractors modify asphalt emulsion products with coal tar additives to provide better performance characteristics. This lab experiment simulated three months of UV light a sealer would see in the field using a QUV booth and the results speak for themselves. The modified asphalt emulsion is already fading to gray, while the BioSealcoat still retains its uniform black finish. If beatification is what you’re after, you’ll be resealing less often with BioSealcoat than conventional coal tar or asphalt emulsion products.

Gasoline, Oil, and Chemical Resistance

Unfortunately, fluids that commonly leak from vehicles like gasoline, motor oil, and other vehicle fluids dissolve asphalt because they are hydrocarbons. When these fluids hit asphalt, they react with the binder that holds the small stones together, leaving soft, loose areas that inevitably become potholes, hairline cracks, or worse. It’s important that your parking lot sealer provides excellent resistance to these fluids, as patrons’ vehicles are bound to have leaks.

Of the three choices, asphalt emulsion sealcoats are the weakest on this front too, and often need to be pumped full of additives to provide even the slightest chemical resistance. This is because the hydrocarbons in motor fluids react with them the same way they react with the asphalt binder. Coal tar sealers’ chemical makeup does not react as severely as asphalt emulsion-based counterparts, but is not resistant to damage from oil or gas by any means. BioSealcoat’s chemical makeup does not react to these fluids, and when they come into contact with the product, they merely pool up on the surface, away from the vulnerable asphalt substrate below.

Oxidation Prevention

Exposure to oxygen causes asphalt to lose its elasticity. When this happens, asphalt is more susceptible to becoming brittle and cracking. You can see the process of oxidation when your asphalt fades from its original rich black color to a dull, uneven gray. A high-quality sealcoat will prevent oxidation and keep your asphalt looking fresh. Coal tar sealcoats are known for forming a hard film over sealed asphalt. While this helps with chemical resistance, the film is known to become inflexible and brittle over time. This leads to large chunks of the sealcoat chipping off and leaving the substrate vulnerable to oxidation. Oxidation is evident in asphalt emulsion-based sealcoats when they begin to lose color and fade to gray within a few months of being applied.

Quick Application

You’ll need to close your parking lot to traffic while sealcoating your asphalt. Any property owner understands the inconvenience and interruption this causes for guests and tenants. Depending on the size of your parking lot and the product your sealcoating contractor applies, this process can take hours or even days. The major cause of delays in reopening lots after sealcoating is the required cure time for sealcoat products. If you do not allow enough time for sealcoat to cure, the product will run, stick to tires, and show track marks in its finish. The sloppy appearance you’d be left with is the opposite of what you hope to accomplish when sealcoating your parking lot.

Traditional coal tar and asphalt emulsion products typically require 24-72 hours for no-track dry time. This is largely due to the film thickness the sealcoat needs to achieve acceptable wear and other performance characteristics. Most traditional parking lot sealcoats are applied at 30-40 mils. BioSealcoat, on the other hand, only needs a few hours to achieve no-track dry time since it delivers exceptional protective and aesthetic characteristics at a fraction of the film thickness of traditional sealcoats. With BioSealcoat, you can expect to open your lot to traffic the same day it is sealcoated.

Environmental Concerns

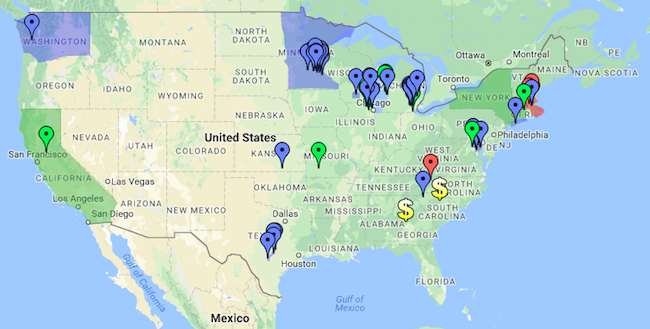

Since 2011, a growing number of states, counties, and municipalities have banned coal tar sealcoats due to growing environmental concerns.

Coal tar sealcoats contain an exorbitant concentration of polycyclic aromatic hydrocarbons (PAHs), a known human carcinogen. These carcinogens make their way into the environment through abrasion from turning tires, water runoff, and airborne volatilization among other things. Anyone who’s ever been near a parking lot or driveway freshly sealcoated with a coal tar product can attest to its harsh odor, which can last for several weeks or even months. These environmental factors give property owners pause when considering specifying a coal tar-based sealer. Asphalt emulsion-based products also give off an unpleasant odor and contain PAHs, but at a much lower concentration. BioSealcoat is one of only a handful of sealcoats certified to have no traceable PAHs based on EPA testing and emits little-to-no odor.

Parking lot sealcoating is an important part of any pavement maintenance program. Be sure to specify a sealcoat that can deliver all the benefits required while minimizing inconvenience and environmental impact!