What Are the Options for Parking Lot Sealcoating?

Parking lot sealcoating a key cog in any pavement maintenance program. The right asphalt sealcoat product prevents harmful substances like gasoline, oil, water, and damaging UV rays from wreaking havoc on the underlying asphalt substrate. But which sealcoat is right for your parking lot? This article outlines the important characteristics to look for in an asphalt sealcoat and explores how different sealers on the market perform.

Before evaluating the parking lot sealcoats on the market, it’s best to first understand the function they have to perform: preserving your parking lot’s asphalt substrate to delay the considerable capital expenditure associated with repaving it. Generally, vehicle traffic is not the root cause of asphalt degradation and failures. Most pavement failures result from:

- Oxidation and Ultraviolet Radiation: Exposure to oxygen causes asphalt to lose elasticity and become brittle, significantly increasing the likelihood of failure. Unfortunately, this process begins the second new asphalt is laid down. You can see this process take effect as your asphalt fades from its original rich jet-black color to a dull, uneven grey. A regular sealcoating regimen will significantly slow this costly process.

- Chemical Exposure: Your parking lot is a temporary home for vehicles. Unfortunately, fluids like gasoline and motor oil essentially dissolve asphalt because both substances are hydrocarbons. These fluids react with the binder that holds the small stones in asphalt together, leaving soft, loose areas that inevitably become cracks and potholes. Since there is no way to ensure all vehicles entering your lot are free from leaks, it’s important to treat your lot with a sealcoat that is resistant to these fluids.

- Freeze/Thaw: Hairline cracks develop over the winter due to the contraction and expansion of the ground underneath your asphalt. If left untreated, water gets into these cracks and causes ridges and upheaval during frost and freezing. After filling these cracks, parking lot sealcoating helps ensure they don’t worsen or reappear.

A sealcoating product worth considering should protect your parking lot from damage caused by UV rays, oxidation, and fluids from vehicles while also preventing water from seeping into the substrate. Property owners should also consider aesthetics and environmental factors when deciding on a sealcoat. With this in mind, let’s take a look at the products available on the market.

Coal Tar Sealcoat

Coal tar has long been the standard for sealcoaters east of the Rocky Mountains. Since its chief ingredient is the byproduct of an industrial process (coking coal), this product is relatively inexpensive. Coal tar sealcoats are known for forming a hard film over the top of asphalt substrates. While this (along with coal tar’s chemical makeup) helps with gasoline and oil resistance, this film is known to become inflexible and brittle over time, and even chip off in large chunks where vehicles are frequently turning (entrances, parking spaces, etc.). This is problematic as the asphalt left uncovered where the chunks that chip off are left exposed to oxidation, chemicals, and other harmful elements. Property owners can expect their lot to take between 24 and 48 hours to reopen for traffic while the sealer cures, depending on square footage and weather conditions.

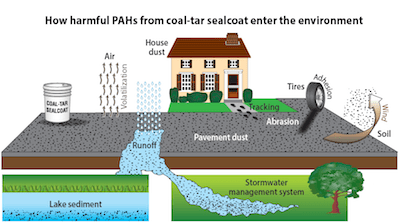

Coal tar sealcoats have come under fire recently for their detrimental effect on the environment—mainly its exorbitant concentration of polycyclic aromatic hydrocarbons (PAHs), a known human carcinogen. These carcinogens make their way into the environment from coal tar in a variety of ways including abrasion from tires, airborne volatilization, and water runoff among others. Since 2011, a growing number of states and municipalities have banned coal tar sealcoats due to growing environmental concerns. But you don’t need a molecular biology degree to anticipate coal tar sealers’ negative effect on the environment. Anyone who’s ever been near a freshly coal tar sealed driveway can attest to its harsh odor, which sometimes lasts weeks or even months after a lot is sealed. These unpleasant environmental characteristics give property owners pause when considering specifying a coal tar-based sealcoat program.

Biobased Parking Lot Sealcoats

Innovation has given way to alternatives to traditional coal tar or asphalt based sealcoats. BioSealcoat® utilizes soybean oil as one of its chief raw materials and is specifically formulated to protect parking lots from oxidation, chemical exposure, UV, and other known enemies of asphalt. The product was also designed with efficiency in mind; the product allows for same day striping and reopening of parking lots, curing 4-5 times faster than conventional products. Parking lots coated with BioSealcoat can be restriped within 2 hours of sealcoating. This is made possible by the formula’s chemical properties, which allows the product to be applied at ¼ the thickness of conventional parking lot sealcoats while providing superior protection. This allows the product to be applied even later into the season than coal tar sealers. BioSealcoat cures to a matte, jet-black finish that is specifically formulated not to fade over time, ensuring a long lasting, uniform appearance. Although biobased sealcoats cost significantly more on a cost per gallon basis, their greater efficiency allows overall project costs to be comparable to other sealers.

BioSealcoat was also formulated with the environment in mind—it is one of only a handful of sealcoats on the market with no detectable PAHs according to EPA testing and emits no harsh odor. As the only USDA Certified Biobased sealcoat on the market, incorporating a biobased sealcoat into a pavement maintenance program can demonstrate a commitment to the environment.

Asphalt Emulsion-Based Sealers

Asphalt emulsions are the most common product in the western United States. Unfortunately, they’re essentially made from the same the same material as your parking lot, so they don’t offer much in terms of protection. While they typically display good water resistance, they’re just as receptive to UV, gasoline, and oil damage as the asphalt itself. Their color tends to fade relatively quickly, sometimes turning gray after only a few months. A parking lot sealcoating program centered around an asphalt emulsion-based sealer will likely require annual resealing, and sometimes won’t even protect the substrate for a full season.

Parking lot sealcoating is an important part of any pavement maintenance program. Once you commit to protecting your asphalt with regularly scheduled sealcoating, be sure to choose the right product for your property!