Industrial coatings appear everywhere. They protect a diverse array of products from corrosion, wear and tear and decay, as well as bringing an aesthetic and colorful appearance to the coated surface or product. With OEM applications ranging from:

Understanding the Different Types of Industrial Coatings

Posted on May 15, 2019 4:46:08 PM by Aexcel

OEM Coating Surface Preparation Mistakes And How To Fix Them

Posted on Sep 17, 2018 3:18:32 PM by Aexcel

Any experienced painter will tell you never to paint a dirty surface. The same is true for OEM paint lines. All well-run paint lines begin with sufficient surface preparation. Improper pretreatment will set any line up for failure regardless of applicator experienced or the quality of the coating. Over the 50 years we've been formulating and manufacturing paint, we've come across more than a handful of paint issues that were ultimately traced back to surface preparation.

How Much Do Industrial Coatings Cost?

Posted on Aug 10, 2018 4:29:21 PM by Aexcel

There’s nothing more frustrating to supply chain managers and purchasing agents than not knowing how much something costs. With that in mind, here are some factors that contribute to the cost of an industrial coating and the effects they ultimately have on price.

Is Working with a Toll Paint Producer Really More Expensive?

Posted on Dec 11, 2017 7:57:00 AM by Aexcel

When facing capacity constraints or dealing with unfamiliar paint chemistries, paint manufacturers often consider utilizing a toll paint producer.

3 Common Problems Toll Paint Manufacturers Can Solve

Posted on Nov 3, 2017 9:52:00 AM by Aexcel

Producing paint, particularly high-performance OEM coatings, is a resource intensive process riddled with potential issues. To avoid these problems, companies often rely on toll paint manufacturers for their OEM coatings.

What are the Benefits of Working With a Toll Paint Producer?

Posted on Oct 16, 2017 4:02:00 PM by Aexcel

Most consumers assume the company whose name appears on a label manufactures the paint. They’re a paint company after all—why wouldn’t they make their own paint? In reality, many companies rely on toll paint producers, third party companies with optimal expertise, equipment, capacity, and other requirements that make them best suited for paint production. Here’s an outline of some factors to consider when deciding on a toll paint producer.

What Are The Advantages of Dip Coating?

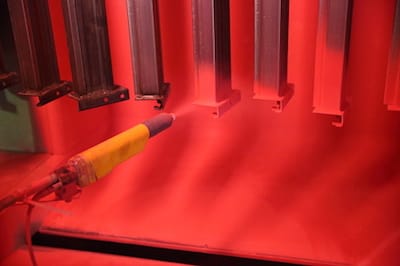

Posted on Jul 24, 2017 8:38:00 AM by Aexcel

Some complex parts that need coating do not lend themselves to spray, powder, or other widely used application methods. Dip coating is the process of choice for finishing materials full of nooks, crannies, and other hard-to-reach areas, provided these hard to reach areas can be drained.

Why a Custom Coating Formulation Is Better than “Good Enough”

Posted on Jul 10, 2017 4:15:26 PM by Chris Hren

The coating on an industrial end product might seem like an afterthought, but it’s far from it. Choosing a coating affects the aesthetic, durability and usability of any product. If you’re involved in the manufacturing process of industrial products, you also know that every material you use affects your process and your bottom line.

Benefits of Using a Custom Soft-Feel Coating I Aexcel

Posted on Mar 29, 2017 7:03:00 AM by Aexcel

Manufacturers have learned to create a sense of high-quality—and even luxury—in their products by adding a soft-feel coating to plastic, metal, and other surfaces. These coatings can be formulated to feel rubbery, velvety, leathery, and nearly anything in-between, to differentiate products from the competition.

Coated Products: What Happens When You Skip the Primer? I Aexcel

Posted on Feb 9, 2017 9:18:22 AM by Aexcel

The application of industrial coatings requires several steps to ensure the end product meets specifications. One of the essential first steps is priming. Unlike consumer grade primers that may often be skipped before a DIY painting project, an industrial primer should never be omitted if you want to maximize the overall quality and feel of your project.